Labels for Safety, Visual and Facility ID Desktop Printers

Paint Stripe Floor Marking Stencils

Valve Lockouts & Hose Lockouts

Safety and Facility Signs and Labels Software

Wire and Component Label Software

Product Identification Label Software

Lockout Tagout Procedures and Tags

SmartID Aerospace RFID Solutions

- Confined Space Signs

- Construction Site Signs

- Electrical and Arc Flash Signs

- First Aid Signs

- Forklift and Warehouse Safety Signs

- Lockout Tagout Signs

- Machine Operation Signs

- Maintenance Signs

- Marine and IMO Signs

- Personal Protection (PPE) Signs

- Radiation and Laser Signs

- Safety Awareness and Compliance Signs

- Slip, Trip and Floor Obstacle Hazard Signs

- Blank Pipe Markers

- IIAR Ammonia Pipe Markers and Components

- Pipe Markers for Acids and Bases

- Pipe Markers for Air and Ducts

- Pipe Markers for Fire Systems

- Pipe Markers for Gases

- Pipe Markers for Maintenance and Operation

- Pipe Markers for Oil

- Pipe Markers for Other Liquids

- Pipe Markers for Steam

- Pipe Markers for Water

Pipe Marker Accessories & Mounting Brackets

Maintenance and Production Tags

Aerospace, Defense and Mass Transit

Datacom , Telecom Identification

What is OEE in manufacturing and 10 equipment visuals to boost your OEE score

Overall Equipment Effectiveness (OEE) is a manufacturing metric that helps determine the degree to which equipment is effectively utilized. Often, it’s a component of an overall lean manufacturing process. OEE is measured by analyzing three critical factors (availability, performance and quality) to help companies gain insight into their equipment's efficiency, identify areas for improvement and optimize their manufacturing process.

The three metrics of the OEE formula

The OEE formula is a calculation that provides an overall OEE score. To get it, you multiply three metrics. They are:

- Availability: The percentage of time that the equipment is available for production. This metric is calculated by subtracting downtime from the total time available for production, then dividing that number by the total time available for production. Note that this metric doesn’t include scheduled downtime, non-production hours or other preplanned time.

- Performance: The speed at which the equipment is producing goods. This metric is calculated by dividing the actual output by the maximum output the equipment can produce in the same time frame.

- Quality: The quality of the output produced by the equipment. This metric is calculated by dividing the number of viable units produced by the total number of units produced.

Availability

Performance

Quality

Overall Equipment Efficiency

Manufacturers strive to hit the OEE industry standard

A perfect OEE score of 100 percent represents the ideal state in which equipment is running at maximum efficiency without any defects or downtime. However, a perfect score is not typically attainable. Instead, manufacturers use OEE benchmarks to gauge their equipment's efficiency.

According to the OEE Foundation, the OEE industry standard for manufacturing processes is 85 percent or higher.1 This typically means that the equipment is producing high-quality products with minimal downtime at maximum speed. On the other hand, an OEE score of 60 percent or less1 indicates significant room for improvement in the manufacturing process. An OEE score in this range can help manufacturers identify areas for improvement.

The Six Big Losses and how they affect OEE metrics

To improve OEE, manufacturers need to identify and minimize the Six Big Losses that can impact their equipment's efficiency and overall score.

|

Six Big Losses

|

Affected OEE metric

|

Examples

|

Visual Solutions

|

|---|---|---|---|

| Equipment failure | Availability |

|

|

| Setup and adjustments | Availability |

|

|

| Idling and minor stops | Speed |

|

|

| Reduced speed | Speed |

|

|

| Process defects | Quality |

|

|

| Reduced yield | Quality |

|

|

10 equipment care visuals that can help boost OEE

Equipment care visuals play a big part in addressing inefficiencies, gaps in maintenance and employee knowledge deficiency. Manufacturers can start to identify and mitigate the Six Big Losses with visual labels and markings.

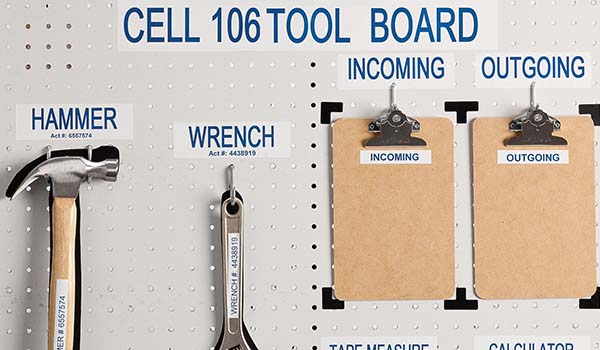

Shadow boards

Prevent “tool walk-off” with shadow boards. Color-code by department or area.

Drive tension guides

Use color to indicate chain or belt tightening or replacement. Label with action steps.

Gauge labels

Give any employee the ability to detect abnormal pressures or temperatures.

Normal/safe-state visuals

Use when putting equipment into a safe working condition or zero-energy state.

Predictive maintenance targets

Ensure vibration and ultrasound probes are positioned for maximum repeatability.

Replacement part visuals

Clearly identify correct replacement parts to eliminate time wasted identifying and ordering.

Equipment ID labels

Enable easier asset tracking, problem reporting and repair history visibility.

Lube point labels

Identify proper grease quantity and frequency, and color code matching lube points and grease guns.

Oil level indicators

Identify low, normal and high oil levels with green-and-red-striped labels.

Max. level indicators

Reinforce stock limits, highlight overstock citations and avoid unnecessarily high inventory.

Get started with Brady

To get started with OEE, start with these four steps

- Identify current OEE score and benchmark it against industry standards.

- Determine the root causes of any inefficiencies or losses.

- Implement strategies to address these inefficiencies and minimize losses.

- Monitor progress by tracking OEE regularly and make adjustments as needed.

A leader in visual workplace solutions, Brady offers numerous products and services to help you minimize the Six Big Losses and raise or reinforce your OEE score.

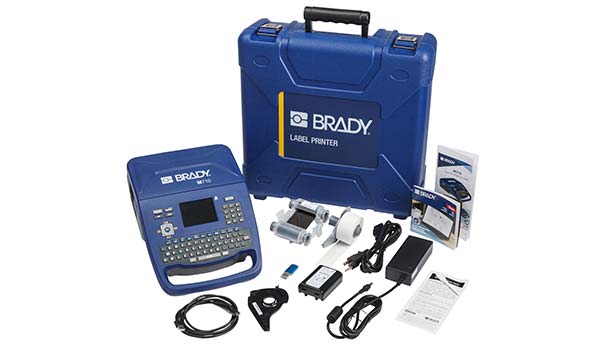

Print your own equipment care visuals

If you’re ready to improve your OEE score, equipment care visuals are a great first step. Bring printing in-house to save on printing and material costs as well as create labels specific to your unique needs and OEE goals. The Brady S3700 Safety Sign and Label Printer with XY Cutter can handle it all. With multicolor printing and a built-in shape cutter, you can create all the custom visuals you need, when you need them.

Shop S3700

More OEE Visual Printers

A leader in visual workplace solutions, Brady offers numerous products and services to help you minimize the Six Big Losses and raise or reinforce your OEE score. Select from handheld portable labelers for labeling on the go, tabletop printers for creating big and bold visuals and much more. Reach out to a Brady rep for help selecting the right printer for your needs.

Shop more printersLearn more about lean manufacturing

Reference

-

"Overall Equipment Effectiveness." Reliable Plant, 29 Apr. 2021,

https://www.reliableplant.com/Read/11785/overall-equipment-effectiveness.