Labels for Safety, Visual and Facility ID Desktop Printers

5S and Lean

5S Lean Manufacturing Guidelines for a Visual Workplace

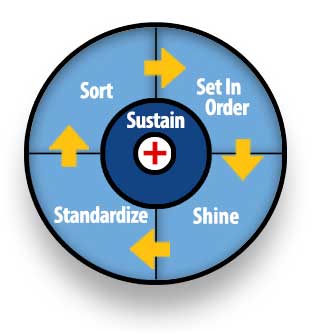

What is 5S?

5S is a Japanese lean methodology designed to reduce waste and optimize productivity through better workplace organization. The five pillars of the 5S are Sort (Seiri), Set in Order (Seiton), Shine (Seiso), Standardize (Seiketsu), and Sustain (Shitsuke).

It's one of the most widely adopted techniques from the lean manufacturing toolbox. "5S Plus" or "5S+1" goes a step further to emphasize a critical aspect of any workplace: Safety.

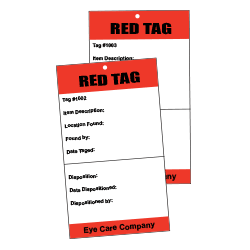

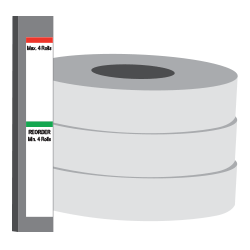

In 5S, visual devices like red tags, floor marking tapes, and shelf labels are used to ensure that there is a place for everything - and everything remains in its place after a kaizen event is over. Likewise, the Standardize and Sustain steps of 5S are virtually impossible to manage without the use of visuals such as check sheets, schedules and audits.

75% of knowledge is gained through visuals

Enhance employee knowledge and create a safer and more productive workplace through 5S lean visuals.

Get a thorough walk-through of each 5S pillar and the benefits of a visual workplace with this FREE guidebook.

Download NowLean 5S Steps

The very first step of 5S is deciding what to keep and what to get rid of. Sort through all of the tools and materials onsite and only keep essential items. Discard everything else to keep your workplace clutter and hazard free.

Look for ways to reduce the sources of waste and errors in your facility and make it more visually instructive. Areas of focus include:

- Organizing equipment

- Establishing safety measures

- Creating procedures

- Establishing product quality standards

- Creating effective inventory & material handling

By eliminating dirt, dust, sources of contamination and other debris, as well as inspecting equipment, you can improve the safety and productivity of your facility.

Expand your efforts and create best practices to develop company standards. This is done with clear and consistent visual controls, roles and responsibilities.

- Job scheduling boards

- Schedules and check sheets

- Supplies checkout boards

- Lead Daily Management (LDM) boards

- Safe state visuals

Ensure employees understand that workplace organization is a top priority and strive to continually improve the workplace. Examples include:

- Dance charts

- Preventive maintenance targets

- Replacement part visuals

- One-point lessons and visuals

Safety is built into the 5S structure in many ways. Identifying potential hazards, risks and preventive safety processes is key to keeping your workforce operating at 100% and more importantly, keeping your team safe.

Product Recommendations

Here are our top product recommendations to get you started.Resources

50 Lean Visuals Handbook

Learn how to use lean visuals more effectively by implementing visual workplace techniques in your facility.

Download Now

Lean Visual Workplace

Learn more about one of the visual workplace in a lean manufacturing process.

/Applications/Lean Visual Workplace

Total Productive Maintenance

Learn more on how to stabilize equipment performance and reliability.

/Applications/Lean Visual Workplace/Lean Visual Workplace TPM