Labels for Safety, Visual and Facility ID Desktop Printers

Brady Safety Arc Flash Services

Protect your employees from the dangers of arc flash

When arc flash safety is your priority

Since worker safety is your main concern, you need a partner that leads the way in electrical safety solutions. Brady is the leader in safety solutions so we know the importance of electrical safety as a whole and our licensed engineers understand the first-hand impact of arc flash risk. We work with your team to create a comprehensive program based on your unique facility and program requirements that ensures your employees are protected.

Arc Flash Services

Our solutions take a proactive approach to Arc Flash safety from NFPA requirements to best practices.

Arc Flash Risk Assessment

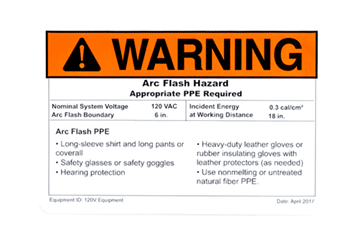

Dedicating internal resources to complete your NFPA Arc Flash Risk Assessment can not only be time consuming, but requires an investment in software and the Arc Flash knowledge behind the assessment. One miscalculation can result in inaccurate PPE protection, non-compliance and even more time spent on rework. Our electrical engineer will complete your assessment, provide you with a detailed assessment report including your single line diagram and install the correct arc flash labels.

Risk Assessment Resources

Engineered Analysis Comparison

View NowRisk Assessment

Sample Report

Arc Flash Labeling Requirements

Learn More

Arc Flash Compliance Review

Changes made in your electrical systems add up over time and it can be hard to keep your assessments up to date. If you have not reviewed your assessment or study within the last 5 years, it is time to audit your Arc Flash Risk Assessment. Let our electrical engineer perform your arc flash audit and ensure your assessment is up to date and compliant.

Infrared Thermography

Electrical equipment can fail due to corrosion or loose connections within the equipment. Equipment failure is not only costly to your business, but it is dangerous for your employees. By using Infrared Thermography to locate hot-spots within your equipment, you can identify these potential problems before they occur. These assessments will show you where minor repairs are needed and the urgency at which to repair before it leads to catastrophic breakdown. Repairs after a thermographic inspection are lower in cost and can be done on your time.

Arc Flash Safety Training

Under NFPA 70E, qualified employees must be able to apply their Arc Flash Safety Training on the shop floor. Our arc flash safety training offerings take a custom approach to training by incorporating both the NFPA guidelines and your company-specific arc flash requirements to ensure participating employees will be able to apply their knowledge to your company’s policies and safely perform their maintenance and everyday workplace activities.

8-hour Safety

- For authorized employees who have not gone through arc flash safety training before. Topics include:

- Shock hazards

- Codes

- Regulation

- Definitions

- PPE

- Approach boundaries

- Labels

4-hour Refresher

- For authorized employees that already have basic electrical knowledge. Topics include:

- PPE

- Approach boundaries

- Labels

- Safe practices

2-hour Awareness

For affected employees who aren’t qualified to perform live electrical work, but need to understand the hazards of the electrical equipment they operate or work near on a daily basis.

2-day Train-the-Trainer

- For those who want to sustain the arc flash training component of their safety program in house. Topics include:

- Full 8-hour arc flash safety training

- How-to present

- Full curriculum materials for future in-house training

Product Recommendations

No program is complete without the labels needed to effectively mark your unique equipmentEasily find gaps in your arc flash safety program

Use our arc flash program checklist tool to quickly identify your needs

Want more information about Brady Safety Services?

Complete our short form and one of our representatives will contact you.