Labels for Safety, Visual and Facility ID Desktop Printers

ANSI Pipe Marking Standards

What are OSHA's requirements related to ANSI Pipe Marking Standards

ANSI Pipe Labeling and Marking Standards

What are OSHA's requirements related to ANSI Pipe Marking Standards?

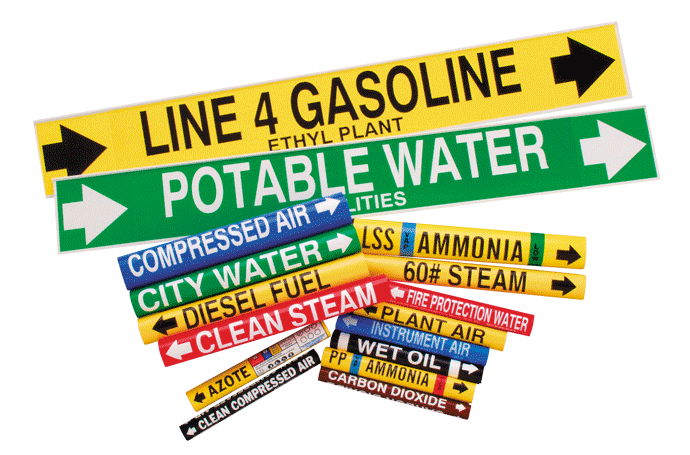

Pipe labeling marking standards are not specifically outlined or defined by OSHA, but standard number 1910.261(a)(3)(i) notes the ASME's (ANSI) standard A13.1 as the recommended scheme for identification of pipe systems.

The ASME Standard for Pipe Identification is a widely used guideline in determining pipe identification requirements. The ASME A13.1-2007 editorial notes indicate that, "A13.1 is intended to establish a common system to assist in identification of hazardous materials conveyed in piping systems and their hazards when released in the environment." It goes on to identify that this scheme provides pipe system identification recommendations for industrial workplaces, power plants, commercial and institutional installations, and buildings used for public assembly.

Editorial Note Source and A13.1-2007 Guide Purchase Information

Brady’s Color and Size Pipe Marking Guide

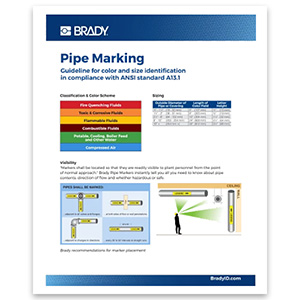

Download a printer-friendly pipe marking color and size guide for the ANSI standard A13.1.

This e-book will explain the cost savings, improving safety, simplifying preventative maintenance, and much more.

Contact Us for a Guide| Label Color | Text Color | Color | Pipe Contents |

| Red | White | Fire-quenching fluids | |

| Orange | Black | Toxic and corrosive fluids | |

| Yellow | Black | Flammable fluids | |

| Brown | White | Combustible fluids | |

| Green | White | Potable, cooling, boiler feed and other water | |

| Blue | White | Compressed air | |

| Purple Gray Black |

White |

|

Defined by user |

| White | Black | Defined by user |

Pipe Marker Visibility and Size Requirements

The ANSI standard A13.1 states that, "Markers shall be located so that they are readily visible to plant personnel from the point of normal approach." They need to instantly tell you all you need to know about pipe contents, direction of flow, and whether the contents are hazardous or safe.

| Outside Diameter of Pipe or Covering | Length of Color Field | Letter Height |

| 3/4" - 1 1/4" (19-32mm) | 5" (127mm) | 1/2" (13mm) |

| 1 1/2" - 2" (38-51mm) | 8" (203mm) | 3/4" (19mm) |

| 2 1/2" - 6" (64-152mm) | 12" (304mm) | 1 1/4" (32mm) |

| 8" - 10" (203-254mm) | 24" (609mm) | 2 1/2" (64mm) |

| 10" (254mm) or bigger | 32" (812mm) | 3 1/2" (89mm) |

What if your pipe or covering outside diameter is less than 3/4 inch or 19 mm?

In cases where it is difficult to label a pipe or covering due to size, we advise using durable and long-lasting energy source valve tags or custom blank tags in place of pipe labels or markers.

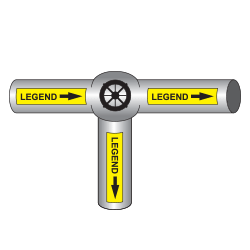

Pipe Marker Placement

Now that we know what our pipe labels need to look like and how big they need to be, we need to understand where they go.

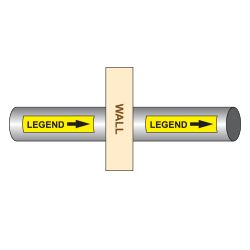

Mark pipes adjacent to all valves and flanges.

Mark pipes at both sides of floor.

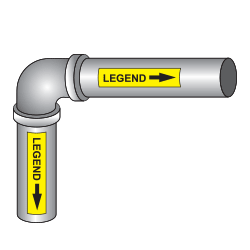

Mark pipes adjacent to change in direction.

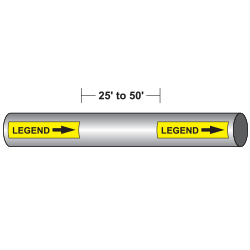

Mark pipes every 25 to 50 foot intervals on straight runs