Labels for Safety, Visual and Facility ID Desktop Printers

Aerospace , Defense & Mass Transit

Brady’s identifying labels and tags are laboratory tested to defy

extreme temperatures, liquids, solvents and generally harsh environments

Aircraft tubing identification

In defiance of aggressive liquids

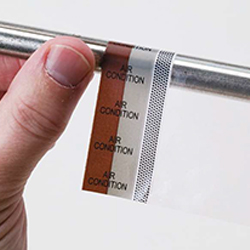

Brady’s Fluid Line Tape, the most widely-used fluid line tape in the aerospace industry, is designed specifically for aircraft tubing identification. This speciality tape, developed in Brady laboratories, defies aggressive hydraulic liquids such as Skydrol™.

Brady's Fluid Line Tape is designed especially for aircraft tubing identification. The subsurface printed, flexible, transparent polyester film tape has a heat activated adhesive. This adhesive offers excellent resistance to fuels, oils, and hydraulic fluids. When the tape is first applied, it can easily be repositioned due to the low initial adhesion.

Properties:

- Colours target MIL-STD-1247C

- Materials performance meets MIL-T-9906C

- Brady's Fluid Line Tape can be used with both thermal transfer and dot matrix printers.

Immovable in extreme heat

Extreme Temperature labels can withstand extremely high temperatures (up to 350°C) and are used to identify printed circuit board & electronic components. They are mainly used for traceability and they offer good barcode printability. To resist extreme heat, Extreme Temperature labels are made out of Polyimide, as opposed to Polyester for normal circumstances.

Brady has a wide range of polyimides available in different colours, all with ESD characteristics, suited for automatic applying and usable in a variety of print technologies.

Measured, weighed, and cleared for heavy duty

Brady Resistant labels are born from one of the most comprehensive R&D programs in the world. They are launched only after extensive laboratory testing and field-testing with solvents, fuels and chemicals. As a customer you can select the durable material you need and print it using the dedicated ribbon to guarantee resistant labels against all types of solvents.

- Metalised Polyester Labels

- White Polyester Labels

- EPREP - Engraved Plate Replacement Labels

- Permashield Labels

- Label printers and Software

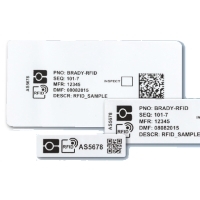

The lightest heavy-duty RFID solution

RFID Integrated Labels provide the entire aerospace ecosystem with a cradle-to-grave data management and lifecycle visibility solution for aircraft items and components. Combined with a high quality print-on-demand system, and ATA Spec 2000 compliant software options, the RFID Integrated Labels are the ultimate tool to simplify and automate aircraft item and component traceability.

Brady's RFID solution will help you achieve:

- Optimised inventory management

- Real-time production visibility

- Improved supply chain integrity

- Increased productivity

- Reduced material expenses

The ultra light weight and flexible B-1000 RFID Alloy Labels provide robust, easy to use and reliable data management and maintenance history visibility for both metal and non-metal components. Its B-1100 RFID Air Label counterpart provides a flexible and ultra-light weight solution with extra read range for non-metal aircraft items.

|

|

| RFID Integrated Alloy Label |

RFID Integrated Air Label |

|

- Ideal for aircraft component tracking on metal and non-metal surfaces - ATA Spec 2000 and SAE AS5678 certified - Print and program on-site in 15 seconds - Self-adhesive - Up to 2 meter read range |

- Ideal for non-metal applications such as life vests, oxygen masks, safety equipment, and other - ATA Spec 2000 and SAE AS5678 certified - Print and program on-site in 15 seconds - Ultra-thin: 0.23 mm - Self-adhesive - Up to 8 meter read range |

The RFID Integrated Labels can be delivered according to specifications, or can be supplied as a component of Brady’s SmartID Solution, which includes a comprehensive onsite label printing, encoding and aircraft asset management system.

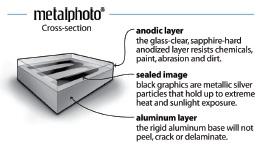

Metal Photo - Exceptionally durable . Widely specified . Photographic Resolution

For more than 50 years, industrial, military and government engineers have specified Metalphoto® photosensitive anodized aluminum for durable labels, nameplates, schematics and control panels installed in harsh operating environments. The proprietary technology of Metalphoto permanently seals a UV-stable image inside of anodized aluminum – offering the confidence of unparalleled durability, image resolution and barcode readability.

Product Benefits

Exceptionally Durable

- UV-stable image is permanently sealed with anodized aluminium

- Virtually impervious to chemicals, heat, abrasion, salt spray and sunlight

- Certified for 20-year plus outdoor applications

- Earned more top scores than any other IUID barcode label material tested

by the U.S. Navy (NSWC, Corona Division, IUID Center, August 2011).

Widely Specified

- Meets a wide array of commercial, government and military specifications

- Notable certifications include:

MIL-STD-130N,STANAG 2290,GGP-455B(3) Type 1,MIL-DTL-15024F,

MIL-P-19834B and A-A-50271

Photographic Resolution

- Photographic image affords extreme detail and contrast at any size

- Anti-counterfeit security printing is available

Most widely used wire and cable markers for a reason

Brady offers a full range of wire & cable labelling solutions. Brady’s self-laminating labels are the most popular wire identification solution in ICT & Telecom, especially used with copper cables, the typical CAT6 or CAT7 solutions. Brady offers specific labels that, when removed, don’t damage a fibre-optic cable. What’s more, Brady fibre-optic cable labels only slightly touch the fibre-optic and never interfere with its data transfer capacity.

Self-laminating labels protect their printing with a water and UV resistant overlaminate, making them suitable for use both outdoors and underground. Our sleeves can be repositioned when applied. Once heated, they are also insulating. The Brady Tag range offers many options including overlaminates and the ability to withstand harsh environments for many years. For panelbuilders, Durasleeves are the preferred solution, allowing identification of cables before or after they are attached.

- Wrap around Labels

- Wire and Cable Sleeves

- Wire and Cable Tags

- Durasleeve Inserts and Carriers

- Label Printers and Software

Heat - Shrink tubing

Brady's heat shrink tubing is Ideal for un-terminated wires or cables needing superior abrasion and chemical resistance.

| Product Name | Description | Temp Range | Specs | Compliance | Rec. Ribbon Series | Printer Compatibility |

|---|---|---|---|---|---|---|

|

B-342 PS and 3PS |

3:1 ratio heat shrinkable tubing |

67℉ to 275℉ (-55℃ to 135℃) |

SAE-AMS-DTL-23053/5C; Class 1 SAE-AS-81531; MIL-STD-202 |

ROHS UL Recognized |

R4300,R6600,R6700(with black sleeve series) |

BMP71,i3300,i7100, BBP72 |

|

B-344 2FR and 3FR |

3:1 and 2:1 ratio Fluid resistance heat shrinkable tubing |

67℉ to 275℉ (-55℃ to 135℃) |

SAE-AMS-DTL-23053/5C; Class 1 SAE-AS-81531; MIL-STD-202 |

ROHS UL Recognized |

R6600 and R6700(with black sleeve series) |

BMP71,i3300,i7100, BBP72 |

B-345 2HT and 2HT |

2:1 ratio low outgasing high temperature heat shrinkable tubing |

55℉ to 225℉ (-55℃ to 437℃) |

NASA SP-R-0022A Outgassing SAE-AS-81531; MIL-STD-202 |

ROHS |

R6000,R6600 and R6800(with black sleeve series) |

BMP71,i3300,i7100, BBP72 |

|

B-7641 LSZH, 2LSZH |

2:1 ratio low smoke Zero halogen heat shrinkable tubing |

22℉ to 221℉ (-30℃ to 105℃) |

SAE-AS-81531; MIL-STD-202 | ROHS | R4300,R6000 and R6600 | i7100,BBP72 |

|

B-7642 HX and 2HX |

2:1 ratio heat shrinkable tubing |

-40℉ to 248℉ (-40℃ to 120℃) |

SAE-AMS-DTL-23053/5;Class 1 &3; SAE-AS-81531;MIL-STD-202 |

ROHS | R4300,R6400, R6600, 356126 series | i3300,i7100,BBP72 |

|

B-7646 DR and 3DR |

3:1 ratio Diesel resistant heat shrinkable tubing |

-55℉ to 135℉ (-48℃ to 57℃) |

SAE-AS-81531; MIL-STD-202 Method 215k; NF F00-608 Type A and H |

ROHS | R6000 | i7100,BBP72 |

BBP 72 - Print accurate double sided heat shrink sleeves for wire and cable in half the time

The BBP®72 Double-Sided Sleeve Printer is the ultimate sleeving solution for printing two-sided heat shrink sleeves. Designed to print on both the top and the bottom of the sleeve simultaneously, the BBP®72 Double-Sided Sleeve Printer creates sleeves in a seamless one-pass operation.

Together with Brady ribbon,

the heat shrink sleeves for the BBP72 printer meet the following specifications:

-SAE-DTL-23053/5 Class 1

-SAE - M-81531

-MIL-STD-202

-Ul Recognized

-CSA Accepted

Standards, Requirements and Specifications

Brady is always pushing forward to adhere to the latest and most advanced industry standards. For a complete list of standards, or for specific requirements, please contact us. We are always ready to add your requirements to our extensive laboratory test plan.

Brady offers specific identification products that are compliant with:

- AS9100D

- MIL-STD-202G (MIL-STD: Military standard –USA)

- Physical properties (e.g. method 215K – solvent resistance)

- Environmental test

- Electrical characteristics

- G: latest version

- MIL-STD-1247C

- MIL-T-9906C

- SAE-AS-81531 (Society of Automotive Engineers)

- SAE-AMS-DTL-23053/5 Class1 (Aviation Maintenance Spec. - Flame resistant).

- ASTM E162 - American Society for Testing and Materials.

- Standard test method for surface Flammability of materials using a Radiant Heat Energy source.

- ASTM E662

- Standard test method for Optical Density of Smoke Generated by solid materials.

- Boeing BSS 7239

- Bombardier SMP 800-C

- RoHS compliant – Restriction of Hazardous Substances.

- Lead, Mercury, Chromium, Cadmium, Brominated flame retardants.

- UL recognised

- UL696 (Underwriters Laboratories): marking & labelling is approved towards this US test method.

- CSA accepted (Canadian Standard Association): marking & printing is approved towards this Canadian test method.

- DIN VDE 0472 Part 815 requirements: method to determine Halogen content.