Labels for Safety, Visual and Facility ID Desktop Printers

How to select a wire marker for your next job

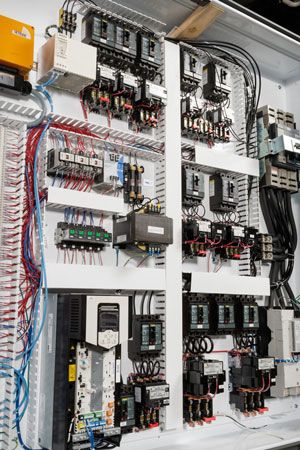

An effective wire marking system can make all the difference when on the job. If you’re just getting started with the process of marking wires, it can be a bit overwhelming. Read on to determine which wire marker label option is best for your next job.

5 considerations when selecting a wire marker

To help you identify the ideal wire marker for your unique application, we’ve identified the five most important considerations to assist you in your selection process.

Marker durability

Who wants to go through the trouble of marking a wire, only to have to replace them when they didn’t stand up to environmental elements? Definitely not you. Save yourself the time and headache by ensuring you’ve selected the right material for your application. A few factors to consider:

- Will the wire markers be in contact with oil, water, chemicals or solvents?

- Does the application need self-extinguishing properties or requirements?

- Is there any government or special specification requirements?

- Are there any other environmental factors that need to be considered such as dirt or weather?

Marker material options

Brady has a variety of wire marker material options that stand up to your biggest environmental challenges. Our top materials for wire markers include:

- Polyolefin wire markers and sleeves remain legible in wet environments and have excellent resistance against chemicals and high temperatures.

- Vinyl wire markers offer excellent oil and dirt resistance and are ideal for non-flat sub-surfaces.

- Nylon wire markers offer excellent resistance against chemicals and hot and cold temperature ranges. Nylon is ideal for curved surfaces and is incredibly strong and flexible.

Marker types

Next, it’s important to consider your wire marker options based on your application. A few questions to ask yourself:

- Do you need a temporary or permanent wire marker?

- Do you prefer adhesive or non-adhesive wire markers?

- How much information do you need to fit on the label?

Once you’ve determined your wire marker application requirements, it’s easy to narrow down which marker type will work best for you.

- Wrap-around markers — Self-laminating or repositionable wrap-around labels are a permanent or temporary solution that provide fade and abrasion resistance.

- Rotating wire labels — On open and closed connections, use rotating wire labels. You can read them easily from any angle as they spin freely around Cat 5/6 and fiber optic cables.

- Flags — Use a P- or T-shaped flag label when you want to limit contact surface between your wire and identification solution, while also maximizing label space to print on. This is a great solution for labeling wires that are already attached. Tags can be used as a non-adhesive alternative.

- Tags — Tags offer a lot of space for identification data and provide tear, solvent and heat resistance for indoor and outdoor use. Tags are usually attached with cable ties.

- Sleeves — Sleeves can be moved along a wire until heat shrunk into position. This enables you to adjust sleeve position once cables are terminated. The sleeve needs to be slid over the cable before termination.

Gauge size

Wire gauge size plays an important role in determining that self-laminating / wrap-around markers perform as expected and ensure the sleeve diameter fits the wire you’re using. Depending on the thickness of your wires, you’ll need to decide which sleeves or wrap-around labels to use in order to make sure they’ll fit. Use these tips to narrow down your selection:

- Sleeves should have at least twice the height of the cable diameter

- Self-laminating wire markers should be +/- 6,5 times the cable diameter (2r x 2pi)

- Wrap-around label markers should have +/- 3,5 times the cable diameter (2r x pi)

- Very thick wires can be identified using straps and a wire bundle tag

If you’re looking for a more versatile option, our wrap-around markers can be used for a range of wire gauge sizes in a pinch.

Marker location

An important consideration when selecting wire markers is whether you’ll be marking the wire before or after termination.

- Before termination — Because wire marker sleeves must be slipped over the open end of a wire, they can only be used before termination. These non-adhesive wire markers provide flexibility as they can be moved prior to being heat-shrunk. Once shrunk, these markers will provide a permanent marker which will stand up to harsh environments.

- After termination — Self-laminating and wrap-around wire markers can be used either before or after termination. When using a wrap-around marker, the legend is visible from all sides since the marker completely wraps around the wire. A self-laminating marker includes a clear portion of the label that, when applied, will wrap around and laminate the legend, protecting it from spills and scratches.

Wire markers without the wait

Depending on what your specific project requires, pre-printed and print-your-own wire markers both have their benefits.

- Pre-printed wire markers — Pre-printed labels give you the opportunity to shop around for the particular label you need, input your information and place an order. This solution is ideal when a low quantity of labels is needed. However, the biggest downfall of pre-printed markers is waiting for the labels to arrive after the order is placed.

-

Print-your-own wire markers — Whether you want more flexibility on the job site or you just don't have time to wait for your labels to arrive, print-your-own wire markers are the perfect solution. By investing in a portable Brady printing solution, you can even save you a trip back to the office when you label needs an unexpected change.

There's so much more our commercial label printers can do beyond printing wire markers. They can also create arc flash and lockout tagout labels, as well as organizational and inventory labels to help keep storage areas and work spaces organized.

Defeat annoying rework and increase productivity

Hand-applying labels can bring any teams' productivity to a standstill. Take the manual labeling process out of your hands and use automation to move through your work more efficiently and reduce rework. Our print and apply machines, help you:

- Increase productivity — cut your labeling time in half to keep your output numbers high

- Reduce errors — get sustainable, consistent identification without the rework

- Make changes fast — intuitive full-color touchscreen and user interface make changing settings easy

Wraptor™ A6500 Wrap Printer Applicator

Ironically, the world can't go wireless without the addition of more and more wires and cables. Keep up with the ever-growing pace with the Wraptor A6500 Wrap Printer Applicator. Print and apply your self-laminating wrap labels in as little as five seconds so you can efficiently move through your work. You also get:

- Connectivity options — three USB ports and 32GB of internal memory to store your commonly used jobs

- Identification options — identify wires and cables from 0.060 to 0.600 in. diameter with one machine

BradyPrinter A5500 Flag Printer Applicator

Adding a flag gives you the room for the data you need, but can also increase your identification time. Free up your flagging time with the BradyPrinter A5500 Flag Printer Applicator.

- Consistent application — labels are applied evenly without wrinkles, skew or edge mismatch to reduce rework

- Connectivity options — get your data to your machine in a variety of ways, including Wi-Fi

- Reduce waste — print and apply serialized labels as you go without having to go back and reprint a full batch if an error occurs