Labels for Safety, Visual and Facility ID Desktop Printers

NFPA 70E 2018 Changes

The NFPA 70E gets updated every three years. See what’s new in 2018.

Overview

The 2018 update includes some of the following changes:

- Continued emphasis on training

- Distinctions between employer and employee responsibilities

- A greater focus on hazard elimination.

- Required job safety plan documentation with risk assessments

Training Requirements

Retraining should still occur every 3 years, and the 2018 update indicates that employees must also be retrained if their job duties change, or when procedures are not being followed (as observed by annual inspections or supervision).

Training should include:

- Specific hazards associated with electrical energy

- Special precautionary techniques and safety related work practices

- PPE, insulating and shielding materials, insulated tools and test equipment

- Emergency response and AED training

- Skills and techniques to distinguish energized parts determine nominal voltages

- Approach distances

- Decision making process and ability to perform job tasks

Training sessions must be documented and verified at least annually, and participants must be able to demonstrate knowledge. To help keep your workplace safe and compliant, Brady Safety offers a custom approach to Arc Flash Training.

Employer vs. Employee Responsibilities

Previously, NFPA 70E just addressed the employer when it came to safety-related work practices. Now this section is subdivided as follows:

Employer:

Establish, document and provide training

Employee:

Must comply with safety related work practices and procedures provided by the employer

Equipment Labeling

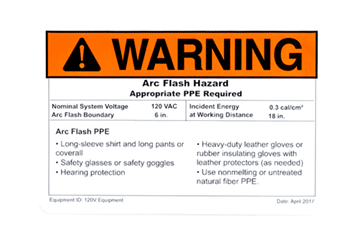

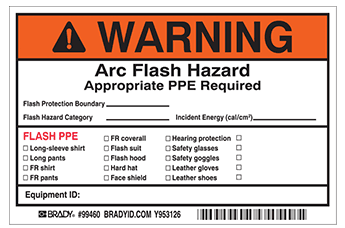

Old Label Versions. The recent update allows labels applied prior to the effective date of this edition of the standard to be acceptable if they complied with the requirements for equipment labeling in the standard in effect at the time the labels were applied (unless changes in electrical distribution system render the label inaccurate). See the Seven Elements of an Arc Flash Label.

Document and Review. Document the method of calculating and the data to support the information for the label and review for accuracy at intervals not to exceed 5 years. Where the review of the data identifies a change that renders the label inaccurate, the label shall be updated.

The owner of the electrical equipment shall be responsible for the documentation, installation and maintenance of the marked label.

Browse Brady’s Arc Flash LabelsEstablishing an Electrically Safe Work Condition

Exception for “Simple Procedures”: When it comes to equipment that is cord- or plug-connect – for which exposure to the hazards of unexpected energization is controlled by the unplugging of the equipment from the energy source, and the employee performing maintenance is under exclusive control of the plug – lockout tagout is not required.

The 2018 update also added two additional steps to the process for establishing and verifying electrically safe work conditions:

- Release stored electrical energy

Work Involving Electrical Hazards

Shock Risk Assessment was modified to require documentation and more information regarding additional protective measures.

Arc Flash Risk Assessment was modified to identify hazards, estimate the likelihood of occurrence and if additional protective measures are required.

Two methods for conducting an assessment:

- Incident Energy Analysis Method

A Brady Safety electrical engineer can complete your assessment, provide you with a detailed assessment report and install the correct arc flash labels.

Learn about Brady Safety’s Arc Flash Risk Assessment Services