Labels for Safety, Visual and Facility ID Desktop Printers

Lean Visual Workplace

Lean 5S and TPM

Visual Workplace: Lean 5S and TPM

Visual Workplace in a Lean Manufacturing Process Overview

What is Visual Workplace?

In a visual workplace, visual devices are positioned at the point of use, giving employees instant access to the critical information they need, right when they need it. Visuals can easily be understood at a glance, eliminating the wasted downtime that had previously been spent searching, asking, or waiting for information. This model can greatly improve your productivity, cost, quality, on-time delivery, inventory and equipment reliability.

Critical Information at the Point of Need

Creating a visually instructive work environment is the foundation of any successful lean manufacturing initiative.

Contact UsBenefits of Effective Lean Techniques and Management

Productivity Gains

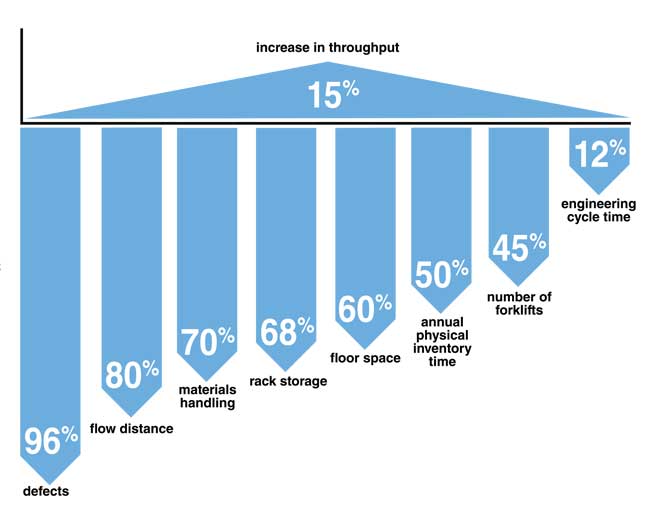

In her book Visual Workplace, Visual Thinking, Dr. Gwendolyn Galsworth states that effective implementations of visual workplace systems have resulted in the following dramatic improvements:

- 15% increase in throughput

- 70% cut in materials

- 60% decrease in floor space

- 80% decrease in flow distance

- 68% reduction in rack storage

- 45% decrease in number of forklifts

- 12% decrease in engineering cycle time

- 50% decrease in annual physical inventory time

- 96% decrease in defects

Eliminates Waste & Information Deficits

Companies are often surprised to learn that only a fraction of their activities actually add value for their customers. It’s not uncommon that 50% or more of a facility’s activities are considered waste! A primary cause of waste is information deficits – employees simply lack the knowledge they need to do their jobs efficiently and effectively. To find the information they need, employees oftentimes waste valuable time and motion searching, waiting, retrieving, reworking… or just plain giving up!

Enhanced Knowledge Acquisition

One of the primary reasons plants around the world have implemented a visual workplace is because of the benefits it offers for knowledge acquisition among employees. Because employees tend to learn by seeing, workplace visuals can play an important role in job training. Visuals make it easier for employees to do their jobs and get their tasks done on time, with fewer mistakes and less stress.

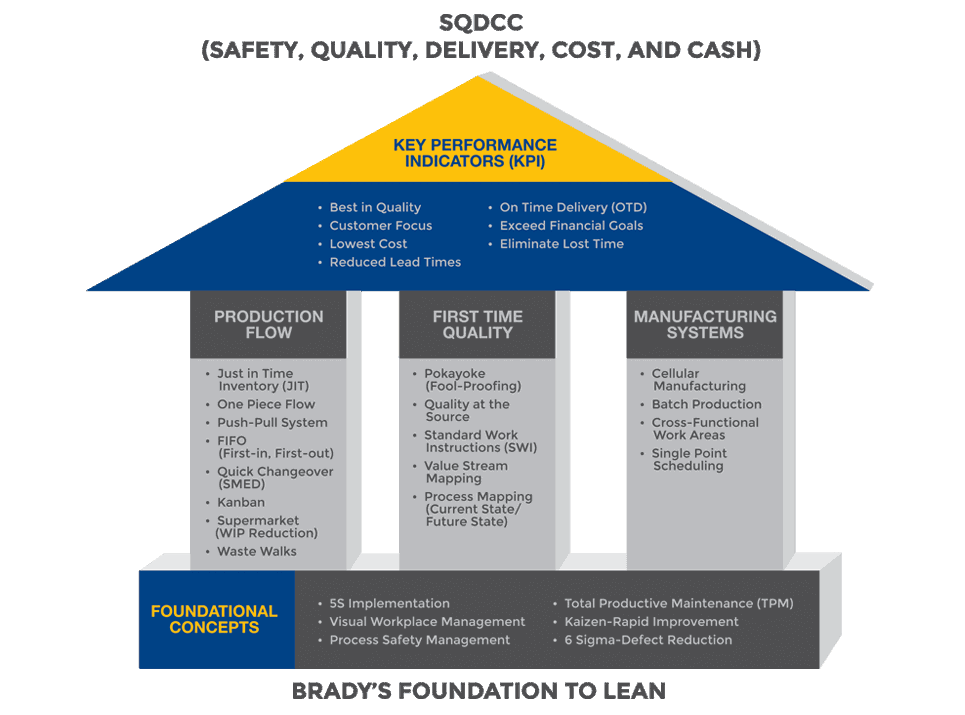

The House of Lean

How Visual Workplace fits into the "House of Lean"

The lean manufacturing system is often represented as a house. The roof depicts the major objectives; the left pillar represents the tools used to speed and smooth the flow of production; and the right pillar represents the tools used to detect errors and prevent defects.

The foundational concepts, including visual workplace, establish a base of operational stability and a work culture dedicated to continuous improvement.

Visual Workplace is the mortar that holds everything together

Visuals reinforce standards and highlight abnormalities. This is especially important during the initial phase of lean when companies are using concepts such as 5S, Standard Work, and Total Productive Maintenance to create a base of operational stability.

Visuals sustain lean improvements

A continuously improving work environment is a constantly changing one. Gains from A continuously improving work environment is a constantly changing one. Gains from 5S Workplace Organization, Total Productive Maintenance (TPM), Kaizen (Continuous Improvement) and other lean activities will disappear unless the new best practices are embedded in the workplace.

Visuals ensure lean improvements remain clearly visible, readily understood, and consistently adhered to long after the kaizen improvement event is over – and prevent employees from reverting to old habits.

Read more about Trends in Safety Signs and Labels in the Brady article with Safety and Health Magazine.