Labels for Safety, Visual and Facility ID Desktop Printers

Labels: Material Guide

For effective identification, material matters

Materials that suit your applications

Based on your labeling needs and the engineering challenges you face each day, finding the right label is integral to the success of your design process and business overall. Brady offers label materials for your specific needs, including: polyimide, polyester, polypropylene, polyolefin, vinyl, vinyl cloth, weather resistant, temperature indicating, raised panel labels and more.

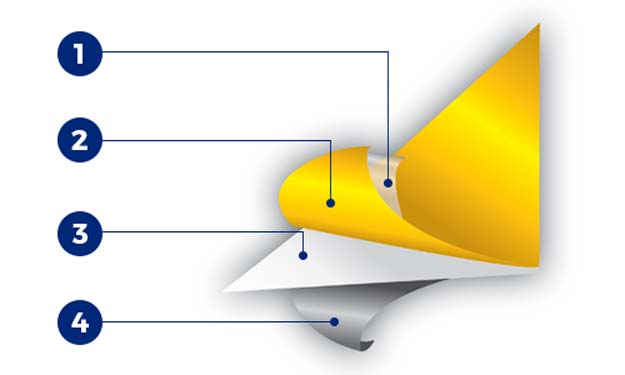

Why Label Construction Matters

When performance matters most, details make the difference, and that’s why each label is built to meet specific application needs. Take a look at the label construction below to see just what goes into a reliable label.

Topcoat — Gives the label its color and finish, receives the print and increases resistance against weathering, chemicals and heat.

Substrate — Gives the label its form and provides mechanical properties, such as tensile strength and flexibility, and physical properties, such as chemical and temperature resistance.

Adhesive

- Acrylic: Excellent all around adhesion characteristics for general application. Also ideal for high surface energy materials and rough surfaces.

- Rubber: Stronger than acrylic for use on low surface energy plastics. This material is sensitive to degradation from elevated temperatures and UV light.

Liner — Is a very thin carrier that protects the adhesive and allows for removability of the label

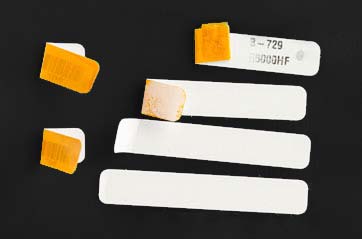

What Could Happen with the Wrong Label

Having the wrong label could lead to disasters in your identification task including wasted time doing re-work, errors in your processes and unhappy customers. The following examples explain what could go wrong if you use the wrong type of label for your application:

Text

You need your labels to keep a crisp and legible legend for effective identification. Using the wrong label could lead to smearing, fading and unreadable text. With the right label, you benefit from durable ink formulas, protective coating options that stand up to your application needs, and legible messages with high-resolution printing and a variety of font sizes.

Topcoat

When your label doesn’t have the correct topcoat for your identification task, the topcoat could peel off the film, leaving the text and label surface unprotected from the elements. The right label topcoat withstands the temperatures, chemicals and other environmental elements in your application.

Film

Using a label with a film that cannot stand up to the high heat you may have in your applications could lead to shrinking or discoloration. Find a durable material that aligns with the environmental challenges your application demands to ensure your label stays intact.

Adhesive

Adhesive is an essential element when it comes to effective identification. The adhesive means your label could lift, fall off, move around or leave residue. Whether acrylic or rubber adhesive, permanent or removable, be sure to find the right adhesive that adheres to the surfaces you require for the duration of your identification project.