Labels by Sign and Label Printer

Paint Stripe Floor Marking Stencils

Valve Lockouts & Hose Lockouts

Safety and Facility Signs and Labels Software

Wire and Component Label Software

Product Identification Label Software

Lockout Tagout Procedures and Tags

SmartID Aerospace RFID Solutions

- Confined Space Signs

- Construction Site Signs

- Electrical and Arc Flash Signs

- First Aid Signs

- Forklift and Warehouse Safety Signs

- Lockout Tagout Signs

- Machine Operation Signs

- Maintenance Signs

- Marine and IMO Signs

- Personal Protection (PPE) Signs

- Radiation and Laser Signs

- Safety Awareness and Compliance Signs

- Slip, Trip and Floor Obstacle Hazard Signs

- Blank Pipe Markers

- IIAR Ammonia Pipe Markers and Components

- Pipe Markers for Acids and Bases

- Pipe Markers for Air and Ducts

- Pipe Markers for Fire Systems

- Pipe Markers for Gases

- Pipe Markers for Maintenance and Operation

- Pipe Markers for Oil

- Pipe Markers for Other Liquids

- Pipe Markers for Steam

- Pipe Markers for Water

Pipe Marker Accessories & Mounting Brackets

Maintenance and Production Tags

Aerospace, Defense and Mass Transit

Datacom , Telecom Identification

Electronics Industry

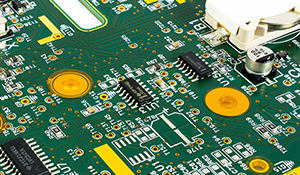

For Years ,Brady’s identification solutions have provided contract manufacturers and original equipment manufacturers in the electronics industry with the benefits of traceability and compliance .

When it comes to traceability, Brady has a long history of providing label materials that are engineered specifically for electronic components. These materials are designed for durability, consistency and compliance in harsh environments and processing conditions, including cleaning, decontaminating and connecting each component. These advantages include:

• Reduction in errors and reworks

• Production cost savings

• Reduced warranty liabilities and returns

• Compliance with trade and substance regulations

Reliable Labels

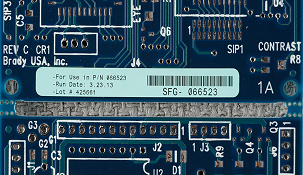

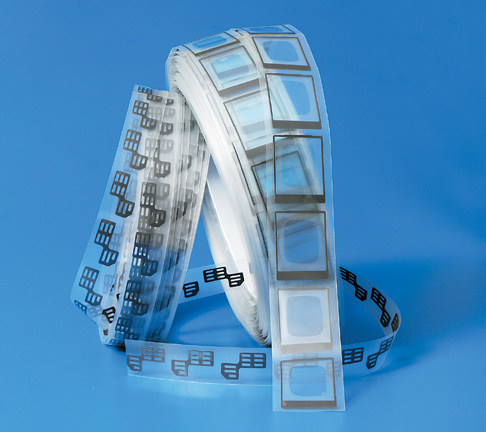

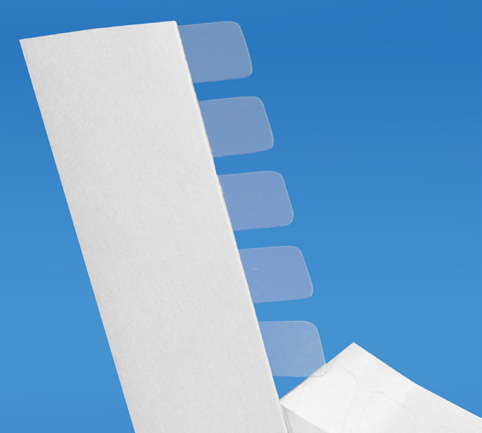

Our range of reliable printed circuit board labels is designed for auto-apply and can keep 2D codes and barcodes legible in PCB manufacturing conditions so they can be read by scanners throughout a production process:

- Polyimide - Print and apply labels:Polyimide labels designed to stay attached and remain legible in temperatures up to 300°C, or when exposed to typical PCB chemicals and cleaning processes.

- Laser Markable Labels: The subtractive marking process of laser markable labels enables them to survive harsh conditions, including high temperatures, extreme abrasion, and repeated harsh aqueous cleaning cycles. Small labels for electrical component boards are no problem — the resolution is so precise it can reach up to 1200 dpi and is limited only by the quality of the laser.

- Kapton Tapes / Masking Tapes: Designed to protect PCB's during manufacturing processes, including wave soldering and hot air levelling. The masking film can be removed cleanl.

- Security Labels: Water indicating label , Temparature indicating labels , Tamper evidence ; Voide labels , Ultra Destructive vinyl labels are widely used on product aswell packaging to prevent counterfeit.

- Overlays: Brady Manufactures durable and high quality Overlays and membranes using latest printing and manufacturing processes to meet most stringent technical and aesthetic requirements.

Automate - Track & Trace

A fully automated printed circuit board labelling solution can enable traceability and manufacturing data analysis without human interference. We can offer several automation solutions depending on your needs:

- BradyPrinter A8500 Label Printer Applicator: reliably automates printed circuit board labelling, consistently prints and applies tiny polyimide labels that can resist the entire PCB production process.

- ALF 14 Label Feeder: offers effective automated label feeding, is fast, efficient and easy to use and can be implemented anywhere along the production line.

- BradyPrinter i7100 Industrial Label Printer: offers durable and highly accurate label printing for business critical high volume identification challenges.

- Scanners: with portable or integrated scanners, traceability systems can evolve beyond supply chain requirements and generate data that can be analysed to create business cases for production optimisation.

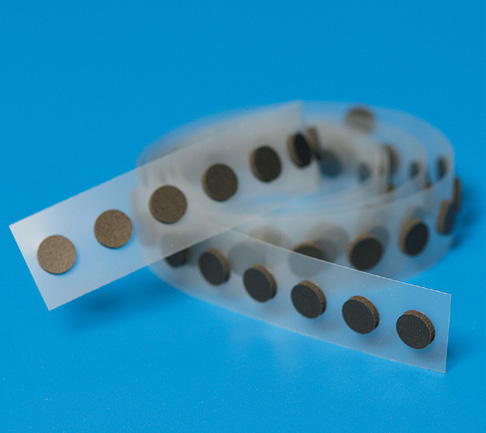

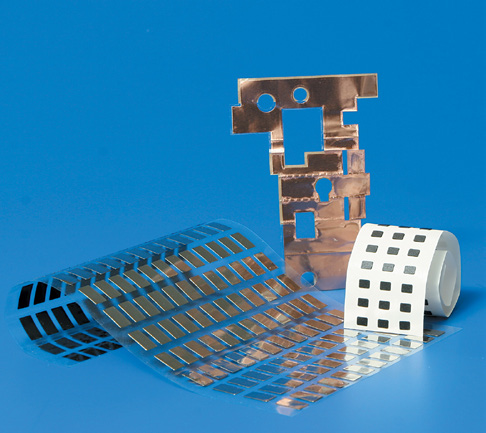

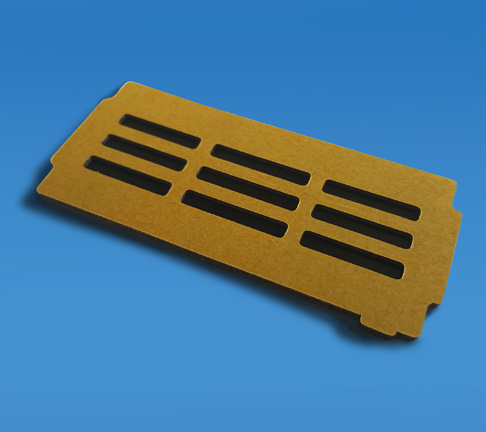

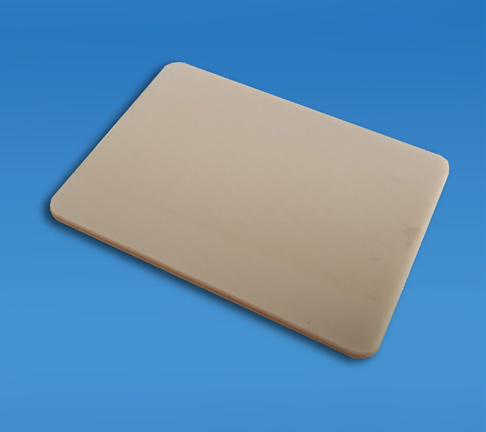

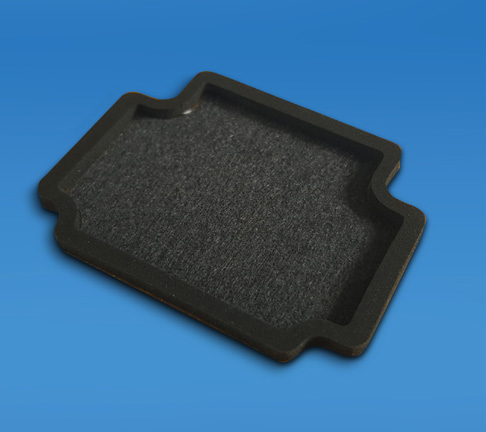

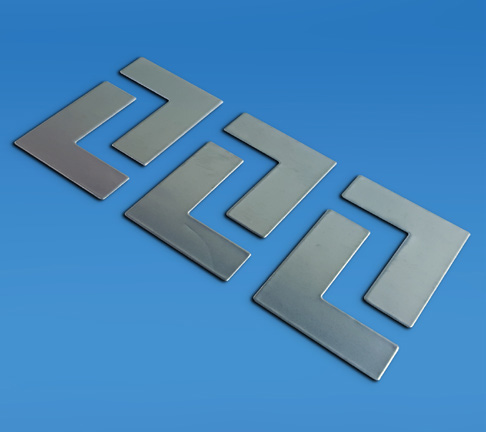

Precision Die-cuts

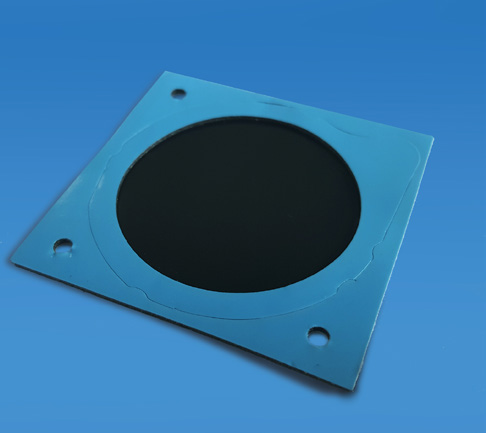

Brady's precision die-cutting solution is an advanced solution for the global precision die-cutting industry. We have rich precision die-cutting technology and decades of industry experience. The global processing and sales network can provide customers with quality services in all corners of the world.

Brady Precision die cut products

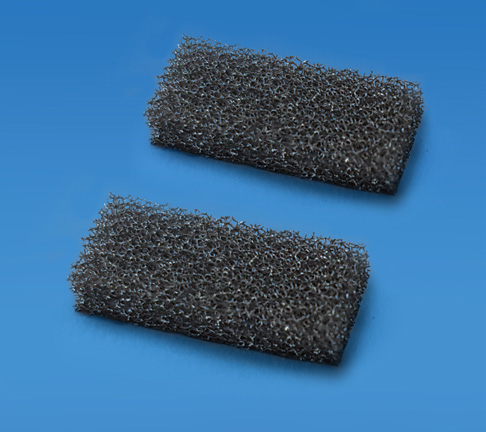

Foam

Foam

Membrane Materials

Membrane Materials

Conductive Foam

Conductive Foam

Acoustic Felt

Acoustic Felt

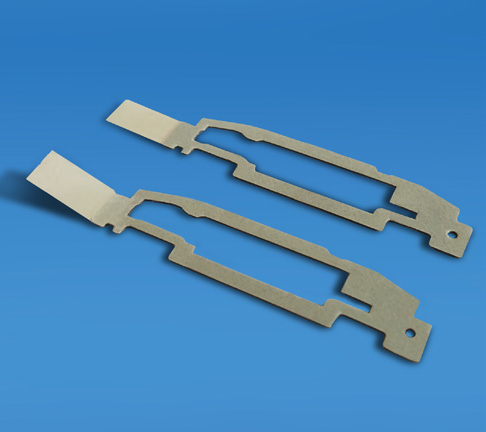

Gasket

Gasket

HP Adhesive

HP Adhesive

Shieding Material

Shieding Material

Slides

Slides

Tim Material

Tim Material

Woven m/Sound a

Woven m/Sound a

Protect Film

Protect Film

Conductive Adhesive

Conductive Adhesive